Ammonia efficiently decomposes into hydrogen and nitrogen under catalyst action; after deammoniation and purification, high‑purity hydrogen is obtained, ensuring safe production. Using green ammonia enables zero‑carbon hydrogen production. The hydrogen is pressurized, stored, and precisely dispensed to vehicles via a sequential control panel and hydrogen dispenser, delivering an efficient and safe on‑site supply solution.

Marca :

RubriCostumização :

support

What is ammonia-based hydrogen production?

We provide a one‑stop green hydrogen solution based on industrial ammonia‑to‑hydrogen equipment. Using liquid ammonia (NH₃) as feedstock, the ammonia is catalytically decomposed under energy‑saving, high‑efficiency ammonia decomposition catalysts, producing a hydrogen‑nitrogen mixture of 75 % H₂ and 25 % N₂. The mixture then passes through a purification unit to obtain high‑purity hydrogen, enabling safe and efficient hydrogen transport.

| Designed hydrogen output (kg/day) | 100-2000 | Ammonia decomposition conversion rate |

>99.5%

|

| Hydrogen production zone area(㎡) | 24-150 | Rated installed power(kW) | 80-2200 |

| Liquid ammonia consumption (kg/h) | 29.53-590.63 | Power supply |

380V/50Hz

|

Our advantages

1. Economy: Low ammonia storage & transport cost, competitive hydrogen price.

2. Convenience: Ammonia readily available, mature logistics; skid-mounted, compact, easy to operate.

3. Efficiency: Low-temp catalysis boosts efficiency & reduces energy consumption; high-purity H₂, high recovery.

4. Safety: Ammonia odor alerts; low temp, explosion-proof.

5. Intelligence: PLC precise control; remote interlock.

Deployment scenario

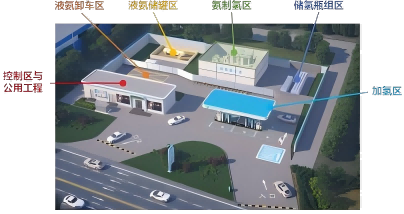

1. Integrated H₂ station: On-site production & refueling for fuel cell vehicles, urban & intercity transport.

2. Fuel cell testing: High-purity H₂ for single cells, stacks, systems; performance & durability tests.

3. Protective gas: For pharma hydrogenation, aerospace propellants, fine chemicals; prevents oxidation, boosts purity.

4. Electronics: Semiconductor wafers, chip welding, specialty gas prep, LCD panel reduction protection.

Low-power - 100kW-class power generation solutions

Low-power - 100 kW class ammonia-hydrogen/pure hydrogen internal combustion power generation equipment , based on liquid ammonia ( NH3 ) is used as a hydrogen storage medium , mainly including two types: hydrogen production through ammonia decomposition and hydrogen fusion internal combustion engines. Core component. It utilizes the high-temperature waste heat exhaust gas from an internal combustion engine, highly integrating it with a low-temperature ammonia decomposition hydrogen production reactor. The ammonia reactor then decomposes ammonia into 75% hydrogen and 25% nitrogen, which, along with ammonia... After the air and gas are mixed, they enter the cylinder of the internal combustion engine, where they are ignited and burned to do work, providing power or generating electricity.

at the same time Our company's 100-kilowatt-class ammonia-hydrogen internal combustion engine has multi-fuel adaptability and is compatible with pure hydrogen, providing technical solutions for pure hydrogen power generation scenarios .

--------------占位---------------